Mineral Extraction

Introduction to Mineral Extraction

The extraction of minerals plays a crucial role in the development and progress of human civilization. As a fundamental process, it involves the exploration, extraction, and processing of various minerals from the earth’s crust. Mineral extraction encompasses both metallic and non-metallic minerals, which serve as essential raw materials for diverse industries such as construction, manufacturing, energy production, and technology.

Definition and Significance of Mineral Extraction

Mineral extraction refers to the process by which valuable minerals are extracted from their geological deposits through mining operations. These minerals can exist in various forms, including ores or mineralized rocks.

The significance of mineral extraction cannot be overstated as it directly supports economic growth by providing resources for industrial activities while generating employment opportunities. Moreover, mineral extraction is indispensable for meeting the ever-growing demands of modern society.

Metallic minerals like gold and copper are crucial in electronics manufacturing and infrastructure development. Non-metallic minerals like coal and limestone are essential for power generation and construction materials production.

Historical Background and Evolution of Mineral Extraction Techniques

The history of mineral extraction dates back thousands of years when early civilizations recognized the value of certain rocks and minerals for toolmaking, pottery production, and trade purposes. Early mining techniques involved simple tools like picks, shovels, and manual labor to extract surface deposits.

However, with advancements in technology over time, mining methods have significantly evolved to meet increasing demands while maximizing efficiency. From ancient civilizations’ primitive techniques to modern-day sophisticated machinery-driven operations encompassing open-pit mining, underground mining systems like shafts and tunnels have revolutionized mineral extraction processes.

The discovery of steam power during the Industrial Revolution further propelled advancements in mining techniques by enabling deeper excavations using steam-powered pumps to dewater mineshaft tunnels effectively. It marked the transition from surface mining to underground mining, allowing access to deeper mineral deposits.

Subsequently, the development of explosives, such as dynamite, revolutionized mining practices by enhancing rock fragmentation and ore extraction efficiency. The integration of heavy machinery, such as excavators and haul trucks, further optimized the extraction process by increasing productivity and minimizing labor-intensive tasks.

Today, mineral extraction techniques continue to evolve with technological innovations such as remote sensing, satellite imagery analysis, and automation. These advancements enable more precise exploration of mineral deposits and safer extraction methodologies while minimizing environmental impacts.

Types of Minerals

Metallic minerals (e.g., gold, copper, iron)

Metallic minerals possess inherent qualities that make them valuable resources in various industries. Gold, with its lustrous appeal and malleability, has been prized for centuries for jewelry and as a store of value. Copper, an excellent conductor of heat and electricity, finds applications in electrical wiring and plumbing systems.

Iron, a vital component of steel manufacturing, is indispensable for construction projects and infrastructure development. These metallic minerals not only contribute to the aesthetic aspects of our lives but also serve as foundational materials for technological advancements.

Importance and Applications of Metallic Minerals

The importance of metallic minerals transcends their intrinsic beauty; they form the backbone of modern society. Gold not only adorns us but also acts as a hedge against financial uncertainty due to its enduring value throughout history. Copper’s excellent conductive properties facilitate efficient energy transfer in power transmission lines and electric devices.

The strength and durability offered by iron-based alloys make them ideal for constructing bridges, skyscrapers, automobiles, and machinery that drive industrial progress worldwide. Without these metallic minerals, the achievements we take for granted in sectors such as healthcare, transportation, energy generation would be significantly hindered.

Major Mining Regions for Metallic Minerals

Metallic mineral deposits are distributed across the globe; however, certain regions stand out due to their abundance or unique geological characteristics favoring mineralization. The Witwatersrand Basin in South Africa is renowned for its vast gold reserves—the deepest mines here reach astonishing depths beyond 4 kilometers (2.5 miles). The prolific copper belt running through Zambia’s Copperbelt Province hosts significant copper deposits that have been extracted since the early 20th century.

Australia’s Pilbara region is rich in iron ore deposits that fuel the nation’s thriving iron ore industry—helping it become one of the world’s largest exporters. These major mining regions not only showcase the wealth of metallic minerals but also reflect the geopolitical dynamics shaping the global mineral extraction landscape.

Non-metallic Minerals (e.g., coal, limestone, gypsum)

While metallic minerals capture our intrigue, non-metallic minerals play equally indispensable roles in our daily lives. Coal, a combustible sedimentary rock, remains a significant energy resource for electricity generation and industrial processes despite increasing emphasis on renewable alternatives. Limestone, composed primarily of calcium carbonate, has diverse applications ranging from construction materials (e.g., cement and concrete) to agricultural supplements that enhance soil quality.

Gypsum, a mineral known for its fire-resistant properties and use in drywall manufacturing, contributes to safe and aesthetically pleasing interior spaces. These non-metallic minerals may lack the allure of precious metals but their practicality and versatility make them essential components of modern society.

Uses and Economic Value of Non-metallic Minerals

Non-metallic minerals fulfill crucial functions across various sectors due to their unique physical and chemical properties. Coal’s primary use as fuel for electricity generation ensures its continuous demand despite concerns about carbon emissions. Meanwhile, limestone serves as an integral ingredient in construction projects worldwide; its versatility extends from road construction to architectural masterpieces like the Pyramids of Egypt or Taj Mahal in India.

The economic value created by non-metallic minerals is not limited to their direct applications but also encompasses industries dependent on these resources. For instance, gypsum’s role in construction drives demand for related products like plasterboard or gypsum-based finishing compounds—boosting employment opportunities while stimulating economic growth.

Prominent Sources and Extraction Methods for Non-metallic Minerals

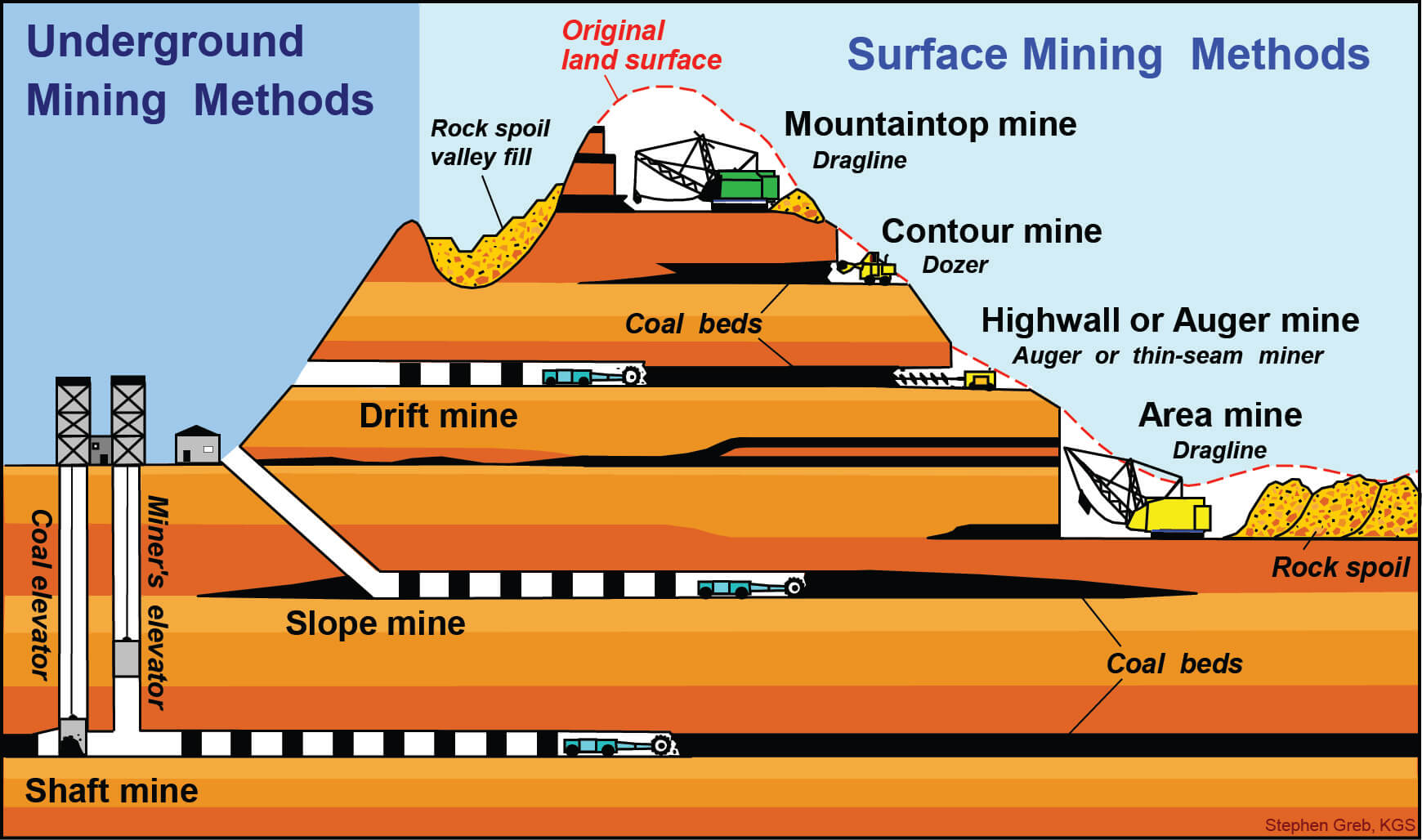

Non-metallic mineral extraction relies on accessing abundant deposits through various methods tailored to each resource’s specific characteristics. Coal is primarily extracted through surface mining techniques such as strip mining or open-pit mining, where overlying layers are removed to access the coal seams. Underground mining methods, such as room-and-pillar mining, are also employed in coal extraction when geological conditions necessitate it.

Limestone and gypsum deposits often occur near the surface, making them amenable to open-pit mining or quarrying operations that involve removing overburden layers and extracting the mineral resource. These extraction methods ensure a reliable supply of non-metallic minerals while maintaining safety standards and minimizing environmental impact.

Mining Techniques

Surface mining methods

Surface mining refers to the extraction of minerals from the Earth’s surface, primarily through open-pit mining and strip mining techniques. Open-pit mining involves digging a large, open pit or excavation in the ground to access mineral deposits. This method is commonly used for extracting metallic minerals such as gold, copper, and iron.

The process starts with the removal of overburden or waste rock to expose the mineral-bearing ore. Specialized equipment such as excavators, haul trucks, and drills are employed to extract the ore efficiently.

a) Advantages and disadvantages of open-pit mining: Open-pit mining offers several advantages including higher production rates due to its ability to extract large volumes of ore at once. It also allows for efficient transportation of mined materials and enables selective extraction of high-grade ores.

However, there are disadvantages associated with this method as well. Open pits result in significant land disturbance and visual impact on landscapes.

Moreover, they require substantial amounts of water for dust suppression during operations. b) Notable open-pit mines around the world: Some prominent examples of open-pit mines include the Bingham Canyon Mine in Utah (USA), known for its vast copper reserves; the Super Pit gold mine in Western Australia; and Mirny Diamond Mine in Russia, one of the largest diamond mines globally.

Strip mining: concept, applications, and environmental concerns

Strip mining is another form of surface mining that involves removing layers or strips of overlying soil and rock to access shallow deposits of coal or other minerals near the surface. This technique is commonly used when deposits are extensive but not deep enough for underground extraction methods.

Strip mining has several applications beyond coal extraction; it can also be utilized in extracting oil sands and phosphate deposits. However, it raises environmental concerns due to its significant impact on land and ecosystems.

The removal of vegetation and topsoil can result in soil erosion, habitat destruction, and disruption of ecological balance. Additionally, the exposure of mineralized materials to air and water can lead to water pollution and acid mine drainage.

Underground mining techniques

Underground mining involves the extraction of minerals from beneath the Earth’s surface using various techniques depending on the deposit’s depth, shape, and density. This method is often employed when deposits are too deep or geologically complex for efficient surface mining.

Shaft mining: process, safety measures, and examples of shaft mines

Shaft mining involves excavating vertical or near-vertical tunnels (shafts) into the ground to access mineral deposits. The process begins by sinking a shaft through overburden layers until reaching the desired ore-bearing zone. Safety measures such as shoring up the shaft walls with timber or steel supports are crucial to prevent collapses.

Notable examples of shaft mines include South Africa’s Mponeng Gold Mine, one of the deepest gold mines globally, and Canada’s Kidd Mine, which specializes in extracting copper-zinc ore. a) Deep shafts vs shallow shafts: Deep shaft mines typically involve greater depths ranging from a few hundred meters to several kilometers below the surface.

These operations require sophisticated ventilation systems to supply fresh air for workers due to higher temperatures and potential gas build-up in deeper levels. On the other hand, shallow shaft mines involve shorter depths that may not require extensive ventilation infrastructure but still demand proper safety precautions.

Room-and-pillar mining: principles, equipment used, and advantages

Room-and-pillar mining is a common technique used in underground coal mining where rooms (openings) are created by removing coal pillars that support the roof. This method leaves behind a series of empty rooms within a network of pillars providing structural stability. Equipment such as continuous miners and shuttle cars are used to extract coal from the rooms.

Room-and-pillar mining offers advantages such as high resource recovery, good ventilation control, and low operating costs. However, it is limited by the size of pillars left behind, which can result in inefficient extraction and some coal being left untouched.

Surface mining techniques like open-pit mining and strip mining are employed in extracting minerals from the Earth’s surface, while underground mining methods such as shaft mining and room-and-pillar mining are utilized for deeper deposits. Each technique has its own set of advantages and disadvantages, along with associated environmental concerns that need to be addressed for sustainable mineral extraction.

Environmental Impact of Mineral Extraction

Impacts on Land: Deforestation, Soil Erosion, and Land Subsidence

Subheading: “The Ravages of Extraction on Earth’s Skin” Mineral extraction takes a toll on the land, leaving behind scars that often persist for decades or even centuries. One of the most significant impacts is deforestation, as vast stretches of forests are cleared to make way for mining operations.

This loss of vegetation not only disrupts ecosystems but also diminishes biodiversity and erodes the natural balance that forests provide. Moreover, the process of mineral extraction unleashes soil erosion, further degrading the land.

Excavation and excavation-related activities expose bare soil to wind and rain, leaving it vulnerable to erosion. The removal of vegetation cover exacerbates this issue as roots can no longer anchor the soil in place.

The consequences are dire: valuable topsoil is washed away, reducing fertility and hampering future agriculture. Furthermore, mineral extraction can lead to land subsidence – a sinking or settling of the ground surface due to underground excavations.

This phenomenon is particularly prominent in underground mining where tunnels and shafts create voids that cause overlying strata to collapse or settle unevenly. Land subsidence poses risks such as structural damage to buildings and infrastructure while altering drainage patterns with potential negative impacts on water resources.

Impacts on Water Resources: Mine Drainage Pollution and Acid Mine Drainage

Subheading: “Tainting Nature’s Lifeline” The extraction of minerals can profoundly impact precious water resources through various mechanisms. One major concern is mine drainage pollution caused by contact between extracted minerals and water sources.

As rainwater or groundwater infiltrates abandoned pits or active mines, it becomes laden with metals and toxic compounds present in the exposed rocks or tailings left behind after processing ores. This contaminated water contaminates rivers, streams, and groundwater, threatening the delicate balance of aquatic ecosystems and potentially jeopardizing the health of communities downstream.

Additionally, acid mine drainage (AMD) poses an alarming threat to water resources. It occurs when sulfur-bearing minerals in exposed rock surfaces react with oxygen and water, resulting in the release of highly acidic drainage.

AMD not only lowers the pH of surrounding waters but also leaches heavy metals from minerals, further contaminating water sources. The consequences are severe ecological damage, including fish kills and loss of biodiversity, as well as potential risks to human health when contaminated water is consumed or used for irrigation.

Impacts on Air Quality: Blasting Dust Emissions and Processing Plant Pollution

Subheading: “The Invisible Assault Above” Mineral extraction operations can have a detrimental impact on air quality due to two main sources – blasting dust emissions and pollution from processing plants.

During mining activities that involve blasting rocks or clearing overburden layers, significant amounts of dust particles are released into the air. These microscopic particles can contain harmful substances such as silica or heavy metals.

Wind disperses them over wide areas, posing respiratory risks for workers and nearby communities while potentially settling on agricultural fields or forests. Furthermore, processing plants used in mineral extraction emit pollutants that contribute to air pollution.

Particulate matter released during crushing, grinding, smelting, or refining processes can contain hazardous substances like sulfur dioxide (SO2), nitrogen oxides (NOx), volatile organic compounds (VOCs), or heavy metals. These pollutants not only degrade local air quality but also contribute to regional atmospheric pollutants responsible for respiratory ailments such as asthma and other chronic diseases.

Mineral extraction has far-reaching environmental impacts across land areas vulnerable to deforestation and soil erosion while causing land subsidence issues. Water resources are adversely affected by mine drainage pollution and the insidious acid mine drainage phenomenon.

Additionally, air quality suffers from blasting dust emissions and processing plant pollution. Recognizing and addressing these impacts through sustainable mining practices is essential to safeguarding our natural world for generations to come.

Sustainable Mining Practices

Reclamation efforts in post-mining areas

One crucial aspect of sustainable mining practices is the implementation of effective reclamation efforts in post-mining areas. Reclamation refers to the restoration and rehabilitation of lands that have been disturbed by mining activities, aiming to return them as closely as possible to their natural state or an alternative productive use. This process involves several key steps, beginning with the removal and proper disposal of mining infrastructure and waste materials.

Subsequently, various reclamation techniques are employed to restore soil fertility, vegetation cover, and water quality. These techniques may include topsoil replacement, contouring landforms, reseeding native plant species, and establishing drainage systems to prevent erosion and runoff.

Reclaiming mined lands requires careful planning, close collaboration between mining companies and environmental experts, as well as adherence to strict regulations. By implementing effective reclamation efforts, not only can the environmental impacts be mitigated or reversed over time but also new opportunities for ecosystem restoration and biodiversity enhancement can be created within previously disturbed areas.

Conclusion

Throughout history, mineral extraction has played a vital role in powering human progress and providing essential resources for our societies. However, it is crucial that we recognize the need for responsible and sustainable practices within this industry.

By embracing technological advancements that promote efficient resource utilization while minimizing negative environmental impacts, we can pave the way towards a future where mineral extraction coexists harmoniously with ecological preservation. While challenges undoubtedly exist in achieving full sustainability in mining operations worldwide, there is reason for optimism.

Companies are increasingly adopting innovative strategies such as environmentally friendly extraction techniques and comprehensive reclamation efforts. Government regulations are becoming more stringent in ensuring compliance with sustainable practices.

Additionally, public awareness about the importance of responsible mineral extraction is growing. By continuing to prioritize sustainability in all aspects of mineral extraction – from exploration to closure – we can protect our precious natural resources, preserve ecosystems, and foster a more sustainable future for generations to come.